Proveedor de botellas de PET

Fabricado en Europa

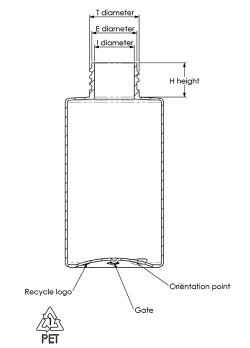

Botellas de PET

Frapak: Su proveedor de confianza de botellas de PET

Desde nuestra fundación en 1978, Frapak ha sido un líder en la industria del embalaje de plástico. Nuestro compromiso con la innovación, el diseño y la calidad nos ha convertido en uno de los principales proveedores de botellas de PET en Europa. Como empresa familiar, nos enfocamos en un crecimiento sostenible y soluciones orientadas al cliente, mejorando continuamente nuestra gama de envases de plástico.

Desde hace más de una década, fabricamos botellas de PET adaptadas a las necesidades de industrias como cosmética, alimentación y farmacia. Desde botellas estándar hasta soluciones de embalaje personalizadas, nuestra experiencia garantiza la entrega de productos de alta calidad que cumplen con las demandas del mercado.

Una amplia gama de botellas de PET y soluciones sostenibles

En Frapak, ofrecemos una gran variedad de botellas de PET, incluyendo:

- Boston Round – Embalaje clásico para productos farmacéuticos y de cuidado personal

- Disc Round & Square – Opciones versátiles para alimentos y cosméticos

- Botellas con gatillo – Ideales para aplicaciones domésticas e industriales

- Embalaje de rPET – Alternativas sostenibles fabricadas con PET reciclado

¿Busca soluciones de embalaje ecológicas? Nuestras botellas y tarros de rPET ayudan a las marcas a reducir su huella ambiental. Conozca más sobre nuestros esfuerzos en sostenibilidad en nuestra Página de Sostenibilidad.

Una década de experiencia en la producción y venta de botellas de PET

Desde hace más de 10 años, Frapak ha estado a la vanguardia de la producción y distribución de botellas de PET, proporcionando soluciones de embalaje de alta calidad a diversas industrias en toda Europa. Nuestro profundo conocimiento de las demandas del mercado, los estándares de la industria y las necesidades de los clientes nos permite ofrecer botellas de PET en stock y diseños personalizados con calidad y fiabilidad constantes.

Nuestra experiencia va más allá de la fabricación; nuestro conocimiento en ventas garantiza que los clientes reciban las soluciones de embalaje adecuadas para sus aplicaciones específicas. Ya sea que necesite botellas de PET estándar o diseños personalizados, ofrecemos una amplia gama de opciones adaptadas a su negocio.

Además, ampliamos constantemente nuestra selección de embalajes de rPET, incluyendo botellas y tarros fabricados con PET reciclado, ideales para marcas comprometidas con el embalaje sostenible.

Botellas de PET en stock y personalizadas para empresas de todos los tamaños

En Frapak, suministramos botellas de PET tanto a grandes empresas consolidadas como a pequeñas empresas en crecimiento. Entendemos que los pedidos mínimos (MOQs) bajos son esenciales para muchos clientes, por lo que nuestras botellas en stock están disponibles con opciones de pedido flexibles.

Nuestras botellas de PET en stock están disponibles en volúmenes de 30 ml a 1000 ml y, por lo general, se ofrecen en PET transparente, con algunos modelos disponibles en ámbar, una opción preferida para aplicaciones farmacéuticas.

Para marcas que buscan envases personalizados, ofrecemos moldes y herramientas a medida para desarrollar envases que se ajusten a sus requisitos específicos. Con el uso de software de diseño 3D (SolidWorks), podemos proporcionar un prototipo digital en pocas horas, lo que permite un proceso de desarrollo rápido y eficiente.

Ya sea que necesite botellas en stock en pequeños lotes o pedidos personalizados de hasta 150.000 unidades al año, ofrecemos soluciones de embalaje de PET de alta calidad para satisfacer las necesidades de su negocio.

¿Por qué elegir envases de PET?

- Claridad similar al vidrio – Los envases de PET ofrecen la misma transparencia y atractivo visual que el vidrio, lo que los convierte en una excelente alternativa para envases de alta gama.

- Ligero y eficiente – Las botellas de PET pesan un 90% menos que el vidrio, lo que reduce los costos de transporte, facilita su manipulación y disminuye significativamente la huella de carbono en la distribución.

- Propiedades de barrera superiores – Gracias al estirado biaxial, el PET proporciona una fuerte protección de barrera, lo que lo hace adecuado para fórmulas a base de alcohol, productos ácidos y químicos.

- Irrompible y seguro – A diferencia del vidrio, las botellas de PET son prácticamente irrompibles, lo que las hace ideales para baños, cocinas profesionales, hospitales y supermercados, entornos donde el vidrio representa un riesgo de seguridad.

La combinación de durabilidad, eficiencia y claridad del PET lo convierte en la opción preferida para industrias que buscan soluciones de embalaje sostenibles, rentables y de alta calidad.