Screw Closures

Product development

Screw Closures

Supplier of screw closures

Frapak Packaging, the foremost leader in high-end plastic packaging production with a state-of-the-art plant and a robust network of five warehouses across the EU, proudly serves as a premium supplier of screw closures.

Our extensive collection of screw closures encompasses a wide array of sizes, with the most popular neck finishes being 20-410, 24-410, 24-415, and 28-410.

Stock of closures

For your immediate needs, we maintain a substantial inventory of screw closures readily available in stock. The colors currently in stock include white, black, natural, and silver.

Should you wish to place an order, we kindly request you to check our Minimum Order Quantity (MOQ) for your desired items.

Check our MOQ.

The closing system of a screw cap

The closing system of a screw caps is important for dispensing the product. The most common closing systems are: plug seal, crabs-claw, liner or insert.

The plug seal is a ring that is designed to seal against the inside wall of the bottle neck finish

The ring angles downward from the inside top panel of the closure and is designed to flex and seal on the top of the neck finish. This system is perfect for PE and PP bottles, less for PET bottles.

The caps are normally supplied with a pre-assembled insert which has a specific opening. When the cap is applied to the bottle the plug closes on the bottleneck and the pin inside the cap closes the plug’s opening.

The closure with the liner presses directly down on the top of the bottle neck finish. The torque of the screw on the bottle neck compresses the foam material and so seals the system

Plastic screw caps

The Pin diameter is dependent on the thickness of the product. .

For low viscose products like facial cleansing or alcohol, the insert opening is 1-3 mm, for high viscosity products like shampoo and body lotions the insert pin is 3-5 mm.

Screw caps liner options

Several liner options are available, the two most commonly-used liners are the foam liner and the induction liner.

Foam liner: The material of the liner is mostly foamed polyethylene. This foam material is available in different densities and can be laminated on both sides with PE, PP, PET or Aluminum.

Induction sealing: Induction sealing uses a special liner to execute the closure. This liner consists of a carrier material and a layer of induction seal material (usually aluminum) which is suitable for the intended bottle material, like PE, PP and PET. When the bottle passes through an induction unit the liner is sealed onto the bottle.

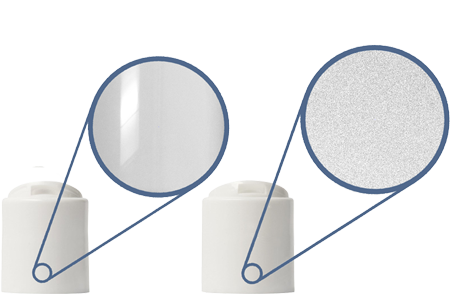

The design of the screw caps

The closures are available in many different sizes, but the most common neck finishes are 20-410, 24-410, 24-415 and 28-410.

In most designs a shiny finish is required but in some cases a matt or frosted effect can add to the design. Frapak, therefore offers both shiny and matt finishes on most sizes of the caps.

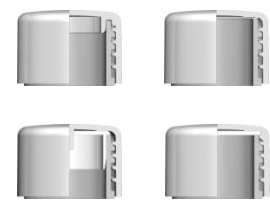

Double wall closures

There are some double wall caps available with a large diameter which ensures a cylindrical design on both HDPE as PET bottles.

These round series are mostly used for hair shampoos and conditioners but can also be used for other applications.

The screw closures are available in many options from small to large, and from smooth to ribbed. They are ideal for a wide variety of products, from cosmetic to household products.