PET bottles supplier

European supplier plastic bottles

Frapak packaging is your plastic bottle supplier, specialising in plastic packaging solutions. Established in 1978, the family-owned company has been actively involved in the packaging market, offering a wide range of innovative standard and bespoke packaging concepts. The company prides itself on maintaining a high quality manufacturing facility to ensure the excellence of its plastic packaging products. We hold an ISO 15593 food grade certificate for the bottles and plastic PET jars.

PET bottles supplier from stock

At Frapak Packaging, we stock an extensive range of PET bottles and offer a variety of items that are readily available for purchase. With five warehouses across Europe, we are well equipped to efficiently meet the needs of our customers.

PET bottle wholesale supplier Volume: Frapak Packaging has a wide range of PET plastic bottles available ranging from standard volumes like 25ml, 30ml pet bottles, 50ml PET bottles, 75ml, 100ml PET bottles, 150ml, 200ml PET bottles, 250ml PET bottles, 300ml PET bottles 500ml PET bottles and 1000ml as well as more special volumes like 20ml, 60ml, 125ml, 300ml, 400ml and 750ml.

To suit all PET bottles Frapak Packaging has a wide range of matching standard closures, pumps and sprayers available from stock.

Plastic PET bottle manufacturers

We have been manufacturing PET plastic bottles since 2010. We use this experience to offer a wide range of standard PET packaging. The successful PET bottle range includes the Boston Round, My Spray, Disc Round, Square, Oval and various Trigger bottles, available in a variety of sizes and many standard neck finishes.

How PET bottles are made is showed in the video of our production facility in the European Union.

Recycling of bottles

In response to the growing demand for recycled plastics, we have expanded our stock to include clear PET containers made from post-consumer recycled materials (rPET). We understand the importance of sustainability and strive to contribute to a greener future by offering recycled options within our PET packaging recycling range recycled PET.

Custom Moulding

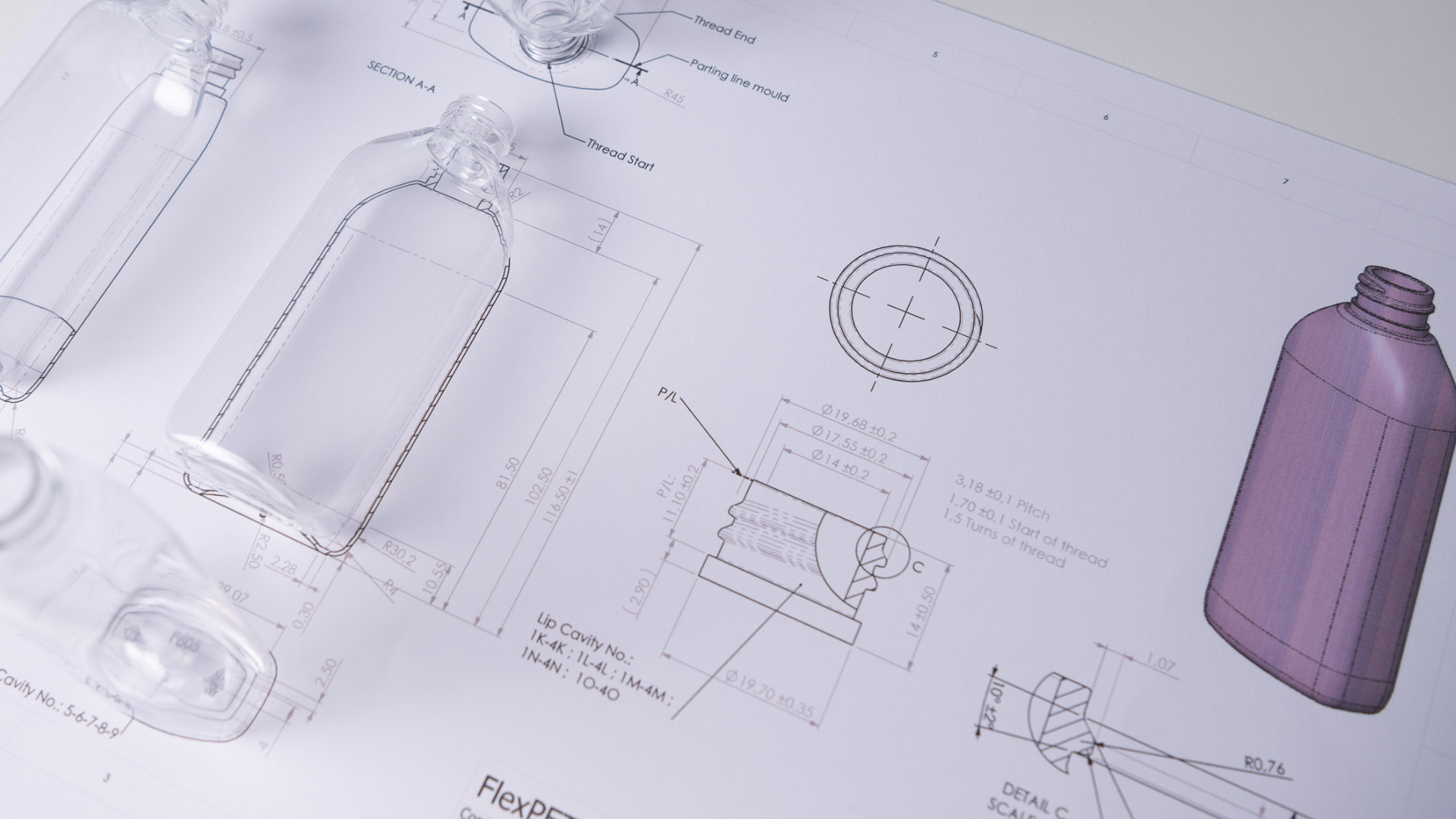

We are PET bottles supplier since 2010 and can offer low MOQs on all our stock items. If a standard bottle doesn't meet your requirements, we can offer custom injection moulded design bottles for any order over 150,000 units per year.

All custom-made designs are created using 3D software such as SolidWorks, which enables us to produce custom designs at low cost. 3D prototypes can also be easily produced in-house as Frapak uses rapid prototyping.

How are PET bottles made?

PET bottle production process:

In the single stage ISBM PET bottle production process, the PET material is dried, heated up and injected into a mould to make a preform which contains already the neck details and the final weight of the end product.

In the second step of the process this preform is conditioned until it has the right temperature profile to enable it to form its final shape. In the third step this preform is stretched and blown into a blow mould which gives it its final shape.

By stretching and blowing the PET material is moved in two directions which is referred to as bi-axial stretch. By bi-axially stretching the preform, the bottle acquires its great characteristics like having clear glass and good barrier properties.

What is PET plastic?

PET (or PETE, PETP, PET-P) is short for PolyEthylene Terephthalate, a thermoplastic polymer which belongs to the polyester group. It is a material which is mainly used in clothing and packaging. PET is made by the esterification of Terephthalic Acid and Ethylene Glycol; its recycling code is number 1.

Here are some key aspects of PET:

What is a PET bottle?

- Durability: PET is known for its strength and resistance to impact.

- Lightweight: It is a lightweight material, which makes it convenient for various uses.

- Transparency: PET can be transparent, which is useful for packaging where product visibility is important.

- Thermal Stability: It has good resistance to temperature variations, although it can deform at high temperatures.

- Chemical Resistance: PET is resistant to a wide range of chemicals, including acids and bases.

- Recyclability: One of the major advantages of PET is that it can be recycled.

Uses:

- Packaging: PET is widely used in packaging, especially for food and beverages, like spices. sauce and dressing bottles.

- Engineering Plastics: In modified form, PET can be used in engineering plastics for high-performance applications.

Are pet bottles recyclable?

- PET is recyclable, which helps reduce its environmental footprint. However, like other plastics, if not disposed of properly, it can contribute to environmental pollution. The production of virgin PET, like other plastics, relies on fossil fuels, which has implications for carbon emissions and sustainability.

Are pet bottles safe?

- PET is generally considered safe for food and beverage packaging. It doesn't leach harmful substances into its contents under normal usage conditions.

What are the main advantages of PET bottles?

- Clear as glass - PET packaging can have the same clarity and appeal as glass packaging.

- Lightweight - PET packaging is on average only 10% of the weight of equivalent glass packaging. This provides great convenience for the consumer, but has an even greater impact on the weight of the overall product - a huge influence on the size of the carbon footprint during transport and handling.

- Barrier properties - PET packaging has excellent barrier properties due to the biaxial stretching of the preform, making it ideal for products containing alcohol, acid or other chemical products.

- Unbreakable - PET bottles are virtually unbreakable, making them ideal for use in settings where glass can be a potential hazard, such as bathrooms, professional kitchens, hospital rooms and operating theatres.

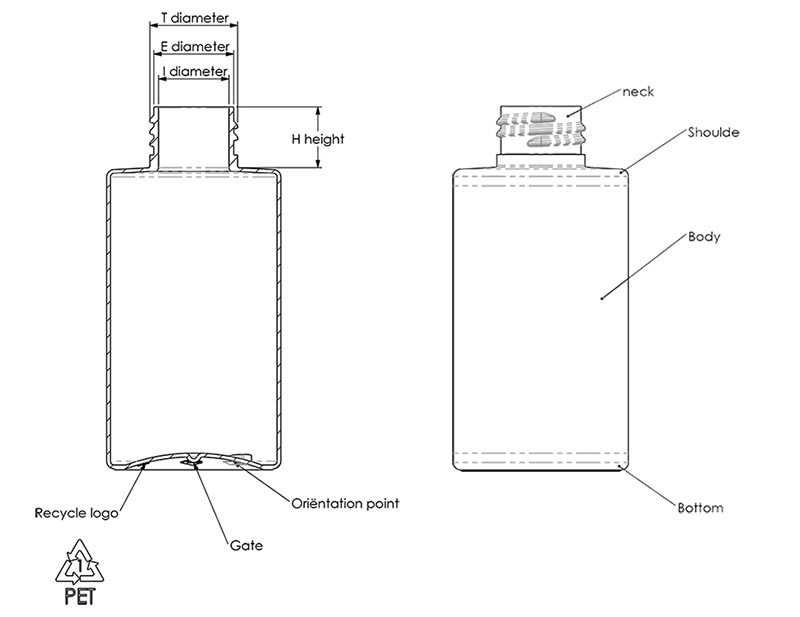

The characteristics of the PET bottles dimensions

The T diameter, E diameter, and I diameter are terms related to the design and dimensions of PET (polyethylene terephthalate) bottles, commonly used for packaging food, beverages, cosmetics and other liquid products. These diameters are important for understanding the bottle's compatibility with closures and machinery used in filling and packaging. Here's a breakdown of each:

T Diameter (Thread Diameter):

- The T diameter refers to the outer diameter of the bottle's thread, where the cap or closure is screwed on.

- It is crucial for ensuring a proper fit between the bottle and its cap, which is essential for product integrity and preventing leaks.

- The T diameter is usually measured across the outermost points of the threading.

E Diameter (Finish Diameter):

- The E diameter is also related to the bottle's neck and closure area but is specifically the diameter of the bottle's neck root diameter.

- It is critical for the compatibility with dispensing systems or pourers.

I Diameter (Inner Diameter):

- The I diameter is the inner diameter of the bottle's body, excluding the neck and opening.

- This measurement is important for determining the size of the closure and for machinery that fills the bottle, as it affects the insertion of spouts or other filling apparatus.

- This measurement is also important for the fitment of plugseal/crabsclaw closures or closures with inserts.

- This measurement impacts the flow of the product when poured and can affect the user's experience.

In summary, the T diameter relates to the external threading for caps, the E diameter to the size of the neck's opening, and the I diameter to the inner space of the bottle's body. Each of these dimensions plays a specific role in the bottle's functionality, compatibility with closures and filling equipment, and overall user experience.

Shape and decoration bottles

Shape: bottles can be blown into round, oval, rectangular or square shapes. The label area will always be slightly curved to secure easy labelling.

Decoration: The product information and the declaration of ingredients are usually presented on the label of the PET bottles. However, alternatively, the PET bottles can also be sleeved or decorated using silkscreen printing or hot stamping. Although PET bottles are mainly used in transparent form, it is possible to colour the bottles during the production process by using a master batch or a liquid colourant.

Bottles with components

By using these standard neck finishes a wide range of closures such as plastic and aluminum screwcap, flip top cap, disc top cap and spout caps are available, as well as a range of sprayers and pumps.

Weight: The weight of the packaging is already determined in the injection moulding of the preform and therefore cannot be easily changed. The manufacturer often chooses the appropriate weight that the bottle should be and determines what particular characteristics are required with regards to top load, drop impact and the ease in which the product can be easily filled, capped and labelled.

Label area: The label area is often defined by a height and a width, based on the circumference of the bottle.