HDPE bottles supplier

Other bottles

Reliable HDPE bottle supplier for diverse packaging needs

As a leading HDPE bottle supplier, Frapak provides high-quality, durable, and customisable packaging solutions tailored to the needs of businesses across various industries. Our bottles are engineered to meet the highest standards, catering to sectors such as personal care, food and beverage, and household products. With advanced manufacturing facilities exceeding 10,000 m² across Europe, we combine cutting-edge production with in-house research and development to deliver innovative and sustainable packaging options.

Why choose HDPE bottles for your packaging?

HDPE (High-Density Polyethylene) bottles are renowned for their strength, chemical resistance, and versatility. They offer a reliable solution for businesses seeking secure and lightweight packaging. Key benefits include:

- Durability: Resistant to impact and chemicals, ensuring long-lasting performance.

- Recyclability: Fully recyclable and available in up to 100% rHDPE material for a sustainable choice.

- Versatility: Suitable for a wide range of products, from detergents to pharmaceuticals.

At Frapak, we manufacture HDPE bottles that are tailored to meet the specific requirements of each application, offering customisable features that align with industry demands.

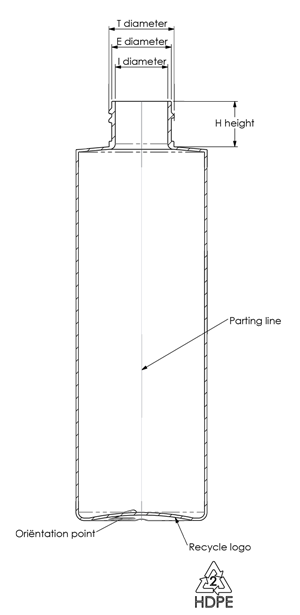

Customisable HDPE bottles for unique applications

Our HDPE bottles are designed to offer a range of options that meet technical and aesthetic requirements. We provide:

- Neck sizes: Compliant with GCMI codes, including 20/410, 24/410, and 28/410 for standard compatibility.

- Volumes: Available in capacities ranging from 10ml to 1 litres, accommodating both sample and bulk packaging needs.

- Shapes and finishes: Choose from cylindrical, oval, and square designs with custom finishes to align with your brand identity.

Every product is manufactured under stringent quality controls to ensure consistency, reliability, and performance.

Addressing challenges with HDPE packaging solutions

We understand that businesses often face challenges when sourcing HDPE plastic packaging, such as ensuring sustainability, maintaining supply chain efficiency, and achieving design customisation. Frapak addresses these needs by offering:

- rHDPE options: Sustainable HDPE bottles made with up to 100% recycled materials, meeting your environmental goals.

- Streamlined production: European-based facilities ensure reliable and efficient supply chains.

- Bespoke designs: Tailored moulding capabilities for unique bottle shapes and branding.

By focusing on these critical factors, we deliver packaging solutions that meet the demands of both functionality and sustainability.

How our HDPE bottle production stands out

Frapak’s state-of-the-art manufacturing facilities and integrated R&D teams enable us to maintain a competitive edge in the plastic packaging market. Key aspects of our production include:

- Innovation-driven approach: Continuous development of new designs and materials to stay ahead of market trends.

- Stringent quality control: Bottles are tested for durability, compatibility, and compliance with regulatory standards.

- High-capacity output: Facilities capable of scaling production without compromising quality or delivery timelines.

These capabilities position Frapak as a trusted partner for businesses seeking a reliable HDPE bottle supplier.

Explore sustainable options with rHDPE bottles

Sustainability is central to our packaging solutions. Our HDPE bottles are available in rHDPE (recycled HDPE), offering an environmentally responsible alternative that maintains the durability and functionality of virgin HDPE. This option supports businesses aiming to reduce their carbon footprint while maintaining high-quality packaging standards.

Partner with Frapak for HDPE plastic packaging

By choosing Frapak as your HDPE bottle supplier, you gain access to a wealth of expertise, resources, and innovative solutions. Our bottles are engineered to meet diverse industry needs while adhering to the highest standards of quality and sustainability. Whether you require standard designs or bespoke packaging, we are equipped to deliver solutions that drive your business forward.

For more information or to request customised HDPE bottle designs, contact us today.