Sustainable plastics

Recycled PET bottles and rPET jars

Frapak is developing many new products. Sometimes we make a series extended with other neck sizes or volumes.

As well we increase our assortiment with sustainable products. Our complete PET assortiment is available in 100% rPET from 25.000 pcs.

We also have rPET bottles on stock and rPET jars on stock.

Do you have questions regarding sustainability?

Sustainable plastics developments

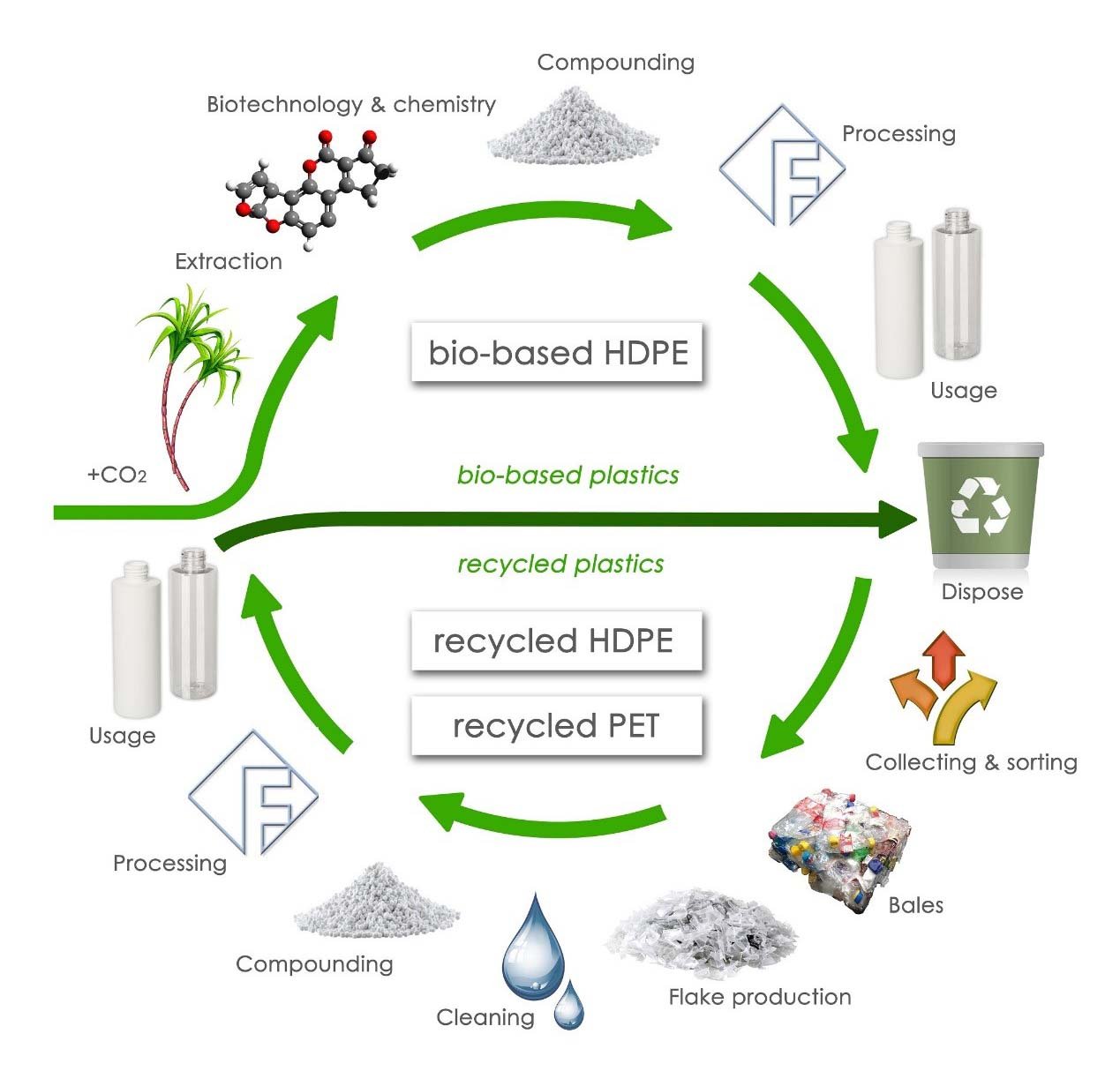

The major advantage of plastic bottles and jars in recycled PET and recycled HDPE is that they form an integral part of the circular economy.

The production of the raw materials saves energy in comparison to the amount used to create virgin plastics, making a significant contribution to the lowering of carbon emissions. The recycling of plastic bottles and jars forms an integral part of this closed loop system and enables them to be used over and over again.

Of course there are also some concerns about using recycled plastics as a raw material; there is no free ride and the sustainable use of plastics comes at a cost.

The main concern for Frapak, as a producer of recycled packaging, is the stability of the raw material and the tightness of the specifications which can lead to cosmetic imperfections.

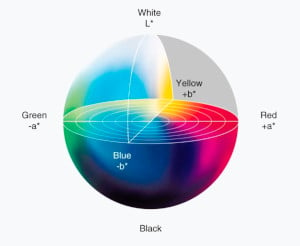

When recycled plastics are used the colour can deviate more, whereas virgin materials have very tight specifications

Sustainable plastics developments

The loop bottle to bottle Sustainable plastics

For the PET and HDPE bottles used in cosmetic, food and chemical applications, recycled alternatives are available and new product lines are being developed and produced for brand owners and retailers on a monthly basis – all contributing to the circular economy

Although plastics sometimes have a bad name when concerns about sustainability are raised, it is important to remember that they also provide society with huge advantages which has led to a better quality of life and environment.

Plastics are lightweight compared to glass and save tons of emissions in the distribution and logistics of products that we use in our daily lives. Plastics are also strong and, as containers, offer a very high level of protection to their contents, preventing spillage, damage and loss.

Plastics are easily recyclable and, right across Europe, the plastics industry is now working hard to close the loop from bottle to bottle as quickly as possible.

The challenge is to create a circular environment where waste is viewed as a valuable raw material and is prevented from escaping the recycling loop.

Creating sustainable plastic

Out of the 3,147,000 tonnes of PET bottles and containers which entered the European market in 2016, some 1,880,900 tonnes was collected (a remarkable 59.8%) and, of this, 1,773,200 tonnes was mechanically recycled.

Recycled PET the LAB value as specified in CIELab

Colouring recycled bottles

For transparent bottles and jars a grey or blue tone which is common for rPET can become an issue. When coloured bottles are being produced the colourant can be adapted in such a way that the recycled tone can actually be corrected. For rPET bottles made in bright colours a mixture of recycled and virgin material achieves the right balance. Recycled HDPE has a typical odour which is common for its application. In the recycling process of HDPE materials this odour can be entirely removed by inserting special provisions in the recycling line.

Bio-based plastics are now being used for the production of HDPE bottles as poly-ethylene can easily be extracted from bio-oil. In Brazil over 18% of vehicles currently run on bio-ethanol which uses the same source as the bio-plastic - sugar cane.

Bio-based polypropylene is technically less feasible because of the lack of C3 polymers in the bio-plastic chain, although mixtures with up to 30% are available.

Bio based Plastics

GREEN plastics

Frapak’s Go green model is based on continuous developments where both recycled and bio-based plastics have their specific role.

The main advantage of BIO-based plastics

The main advantage of bio-based plastics is that society now has a raw material stream with a possibly negative carbon emission value. The main disadvantage is that it is mostly first generation feedstock like corn or sugar cane that is used in its creation which increases the pressure on scarce resources like water and land and intensifies agricultural developments. In the near future, a second generation of feedstocks can be used which are derived from the organic waste streams which should counter the main concerns raised about the use of bio-based plastic.

BIO-based PET is our newest development

Our latest development is bio-based PET or rather PEF (polyethylene furanoate). This bio-based material is not yet available industrially although several pilot plants are currently producing small lots to assess its process-ability and characteristics, to create more sustainable plastics.