Disc top caps supplier

18mm, frosted (plastic)

| 1074 | |

| Square | |

| Plug seal | |

| 25,000 | |

| 8.0mm | |

| White |

18mm, smooth

| 1074 | |

| Square | |

| Plug seal | |

| 25,000 | |

| 8.0mm | |

| White |

20-410, frosted (plastic)

| 1210 | |

| Standard | |

| Plug seal | |

| 4,500 | |

| 8.0mm | |

| White |

20-410, frosted (plastic)

| 1210 | |

| Standard | |

| Plug seal | |

| 4,500 | |

| 8.0mm | |

| Natural |

20-410, frosted (plastic)

| 1210 | |

| Standard | |

| Plug seal | |

| 4,500 | |

| 8.0mm | |

| Black |

20-410, frosted (plastic)

| 1210 | |

| Standard | |

| Plug seal | |

| 54,000 | |

| 8.0mm | |

| Any colour |

20-410, smooth

| 1210 | |

| Standard | |

| Plug seal | |

| 4,500 | |

| 8.0mm | |

| White |

20-410, smooth

| 1210 | |

| Standard | |

| Plug seal | |

| 4,500 | |

| 8.0mm | |

| Natural |

20-410, smooth

| 1210 | |

| Standard | |

| Plug seal | |

| 4,500 | |

| 8.0mm | |

| Black |

20-410, smooth

| 1210 | |

| Standard | |

| Plug seal | |

| 54,000 | |

| 8.0mm | |

| Any colour |

24-410, frosted (plastic)

| 1212 | |

| Standard | |

| Plug seal | |

| 2,600 | |

| 9.0mm | |

| White |

24-410, frosted (plastic)

| 1212 | |

| Standard | |

| Plug seal | |

| 2,600 | |

| 9.0mm | |

| Natural |

24-410, frosted (plastic)

| 1212 | |

| Standard | |

| Plug seal | |

| 2,600 | |

| 9.0mm | |

| Black |

24-410, frosted (plastic)

| 1212 | |

| Standard | |

| Plug seal | |

| 52,000 | |

| 9.0mm | |

| Any colour |

24-410, smooth

| 1212 | |

| Standard | |

| Plug seal | |

| 2,600 | |

| 9.0mm | |

| White |

24-410, smooth

| 1212 | |

| Standard | |

| Plug seal | |

| 2,600 | |

| 9.0mm | |

| Natural |

24-410, smooth

| 1212 | |

| Standard | |

| Plug seal | |

| 2,600 | |

| 9.0mm | |

| Black |

24-410, smooth

| 1212 | |

| Standard | |

| Plug seal | |

| 2,600 | |

| 9.0mm | |

| Silver |

24-410, smooth

| 1212 | |

| Standard | |

| Plug seal | |

| 52,000 | |

| 9.0mm | |

| Any colour |

24-415, frosted (plastic)

| 1077 | |

| Standard | |

| Plug seal | |

| 90,000 | |

| 8.0mm | |

| White |

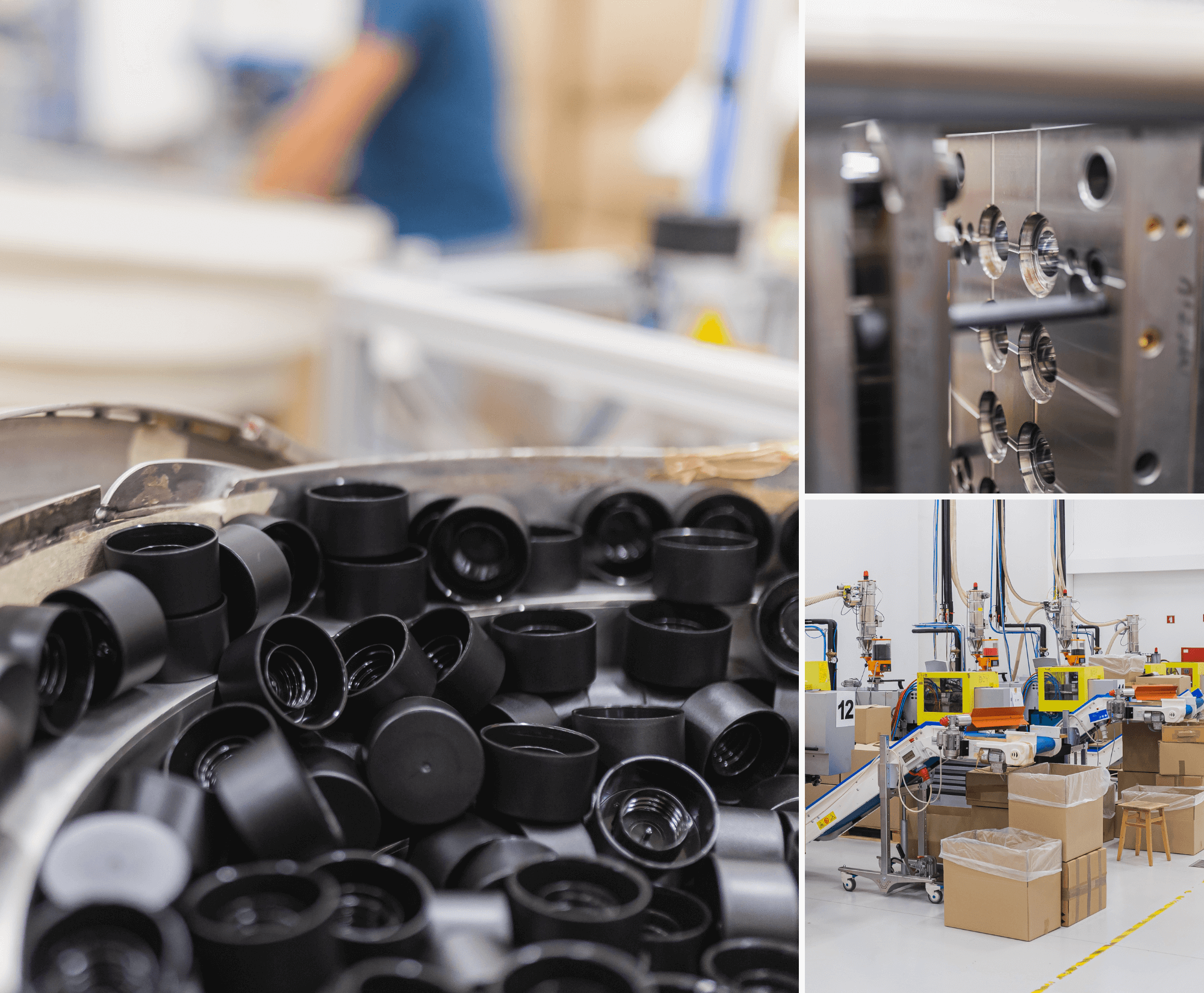

Disc top caps supplier

For years, Frapak Packaging has been a leading supplier of high-quality plastic disc top caps, serving a diverse range of industries. We offer a comprehensive selection of standard disc top caps, accommodating various neck sizes including 20-410, 24-410, 24-415, and 28-410. Our caps are designed for ease of use and reliable performance, making them a top choice for businesses seeking efficient dispensing solutions.

In Stock disc top caps

Frapak Packaging prides itself on its vast inventory of disc top closures, readily available to meet your immediate needs. As a prominent distributor, we specialize in the popular disc top closure design, which features a dual-part construction comprising a robust body and a user-friendly disc. This design ensures a seamless dispensing experience for end-users.

Understanding the urgency of supply needs, Frapak maintains a ready stock of disc top caps in various colors and sizes, including white, black, natural, and silver, in specifications of 20/410, 24/410, and 28/410. We offer these with lower minimum order quantities to accommodate both large and small orders efficiently.

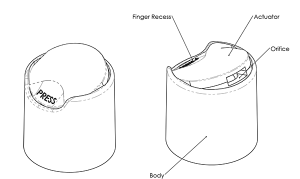

The instructions for a disc top cap

By applying force on the finger pad, the disc of the cap opens and allows the product to flow through the orifice.

This enables the product to be dispensed single-handedly thus increasing customer convenience.

The disc is fitted into the top of the body which, when actuated, rotates on the two pivoting points at the side of the disc. Inside the disc the opening of the body is hermetically closed by a plug seal inside the disc.

Dispensing closures in shiny and matt coloured

The dispensing closures are available with a plug seal or crab's claw in 20-410, 24-410, 24-415 and 28-410 sizes.

In most designs a shiny finish is required but, in some cases, a matt or frosted effect can enhance the design beautifully.

Frapak therefore offers both shiny and matt finishes on all the sizes of the disc top caps.

The newest disc top closure has a large diameter

The latest development is a disc top closure which has a large diameter providing a uniform cylindrical design on both HDPE as PET bottles.

On HDPE bottles the disc top cap has a special orientation point so the front of the closure orifice can be aligned with the front of the bottle.

This unique feature provides a very modern, stable appearance on the product shelf.

Disc top caps for large diameter

This dispensing closure, rounded series are mostly used for hair shampoos and conditioners but can also be used for other applications.

Disc top caps are used for a variety of cosmetic and hair care products like body creams, shampoos and conditioners which are slightly viscous.

Bi-coloured disc top closure

Creating an appealing closure design can be achieved by using the right pigments or colourants. As the disc top cap is made out of two parts which can be coloured differently it allows the closure to be styled to match the bottle underneath.

Adding pearlescent pigments gives the disc top cap a fashionable metallic look. The colours for the disc top caps can be chosen from all the pantone colours currently available bringing the design in line with the label or the colour of the bottle.