Decoration of bottles and jars

In the current competitive market of personal care and cosmetic products it is clear that a distinctive packaging design in combination with outstanding decoration attracts consumers.

Starting in 2019 Frapak is offering the possibility of silk screen printing and hot foil stamping directly from the factory saving precious time to market and logistics costs.

The complete product range of PET and HDPE bottles can be printed fully automatic up to 6 colors in a single process. Also cosmetic jars made from PET, PP or acrylic materials like SAN, SMMA or PMMA can be screen printed and hot stamped in the same location.

Newest development of Screen printing

The screen printing process by means of UV inks offers high gloss or matt finishes and a very good adhesion to the plastic substrates. The latest screen printing technology provides for a perfect positioning of the image in relation to the bottle or jar so a customer’s logo can be aligned with a closure or an embossed logo.

Before the actual screen printing process the bottle is cleaned by means of ionization and conditioned by flame treatment to prepare a perfect surface for the adhesion of the screen print.

All six printing stations are perfectly aligned so color to color prints have near zero tolerances. At the end of the process the printing image can be checked by an in-line camera control system or Decomat fulfilling even the tightest AQL requirements.

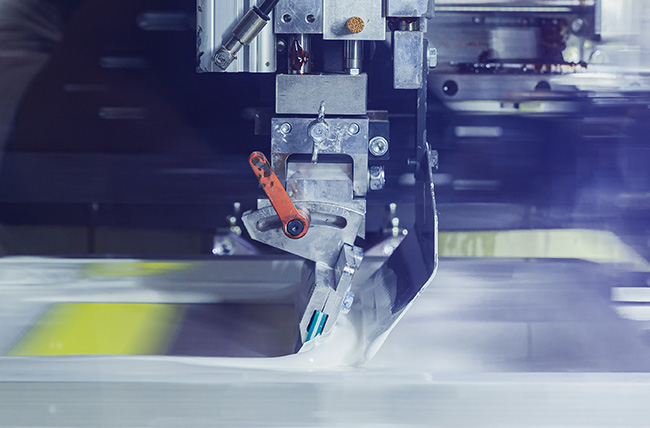

Servo driven screen printing machines

The current technology of servo driven screen printing machines allows for round, oval, conical or flat bottles and jars to be printed in the same quality and speed.

The costs of screen printing are higher when compared directly with the cost of a label however as filling speed and efficiencies are higher on pre-decorated bottles and jars these costs are partially compensated. The orientation and relation of the design on a bottle or jar can also be challenging when using labels whereas for screen printing this is a standard feature at no extra costs.

Applying a hot stamp in combination with screen printing even enhances the quality of your decoration and makes the product standing out on the shelf.

The development on decoration in 2019 allows for hot stamping on all Frapak’s product range and can be combined and adjusted to the screen printed decors.

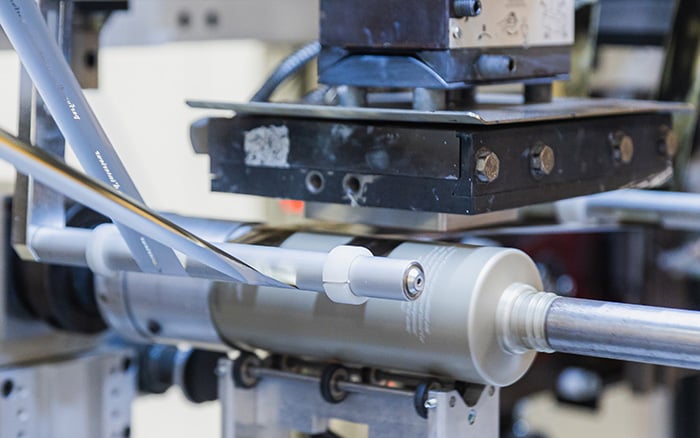

Hot stamping machines

The hot stamping machines feature an automatic infeed and detect the position of the bottle or jar by means of an optical sensor. When the product has been positioned correctly the dye transfers its embossed image by means of heat and pressure onto the bottle or jar. Depending on the design of the decoration the time, pressure and dye must be adjusted to reach the perfect quality.

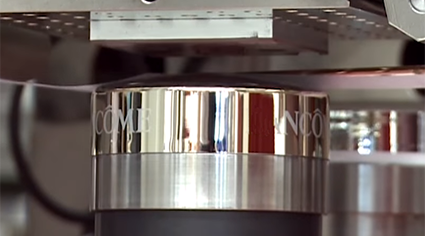

Another possibility for hot foil stamping is creating a metallised ring at the bottom of a closure or lid. This subtle effect enhances the cosmetic appearance and is a classic solution to upgrade the quality impression of your product.

Our supply team has selected the best foil suppliers which are able to offer us access to all foil colors suitable for different materials like HDPE, PP and PET. When the extensive range of standard hot foil colors are not matching your requirements customized foils can be developed and tested in combination with your product.

The adhesion and resistance of foils have been tested in our laboratory and standard quality procedures are followed to ensure the perfect composition of your product. Please consult our account managers how our screen print and hot stamp capabilities can support your brand standing out on the shelf.