Screen printing

Service decoration

Screen printing

Printing

In the screen printing process, the different screens (for each colour) are brought in contact with the bottle or jar in the full colour screen-printing machine, and the ink is released onto the gaps in the mesh in a controlled and prescribed amount.

The screen printing process is sometimes not feasible for complicated and irregular shapes, as the screen on this rotary process cannot come in contact with the desired print area. In these specific cases, tampon printing is used.

In the tampon printing process, an image is transferred from the printing machine onto the item by using a pad and a cliché. The pad absorbs the ink from the cliché, and as the pad is made from flexible silicon, it picks up the ink and transfers the design by pressing it onto the part.

Your Brand is our mission

Setting your Brand or packaging apart from the other products on the shelf can be realised not only by the shape of the bottle, but also by its decoration, as this is a vital part of a distinctive look. Instead of labelling your bottles or jars, you can choose for a printed design, which offers you a sophisticated look. Frapak Packaging provides screen printing on all our bottles and jars, in 1 to 6 colours, in combination with hotfoil.

Contact us now at sales@frapak.com and learn more about our 3D design.

Technology of Screen printing

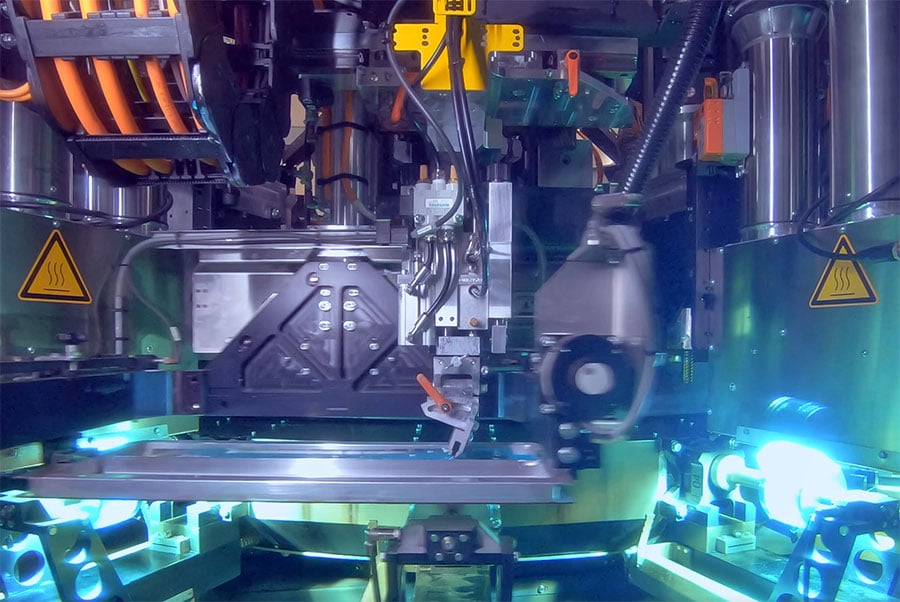

Screen printing machine

The current technology of servo driven screen printing machines allows for round, oval, conical or flat bottles and jars to be printed in the same quality and speed.

The costs of screen printing are higher when compared directly with the cost of a label however as filling speed and efficiencies are higher on pre-decorated bottles and jars these costs are partially compensated. The orientation and relation of the design on a bottle or jar can also be challenging when using labels whereas for screen printing this is a standard feature at no extra costs.

Applying a hot stamp in combination with screen printing even enhances the quality of your decoration and makes the product standing out on the shelf.

The development on decoration in 2019 allows for hot stamping on all Frapak’s product range and can be combined and adjusted to the screen printed decors.

Contact us now at sales@frapak.com and learn more about our 3D design.